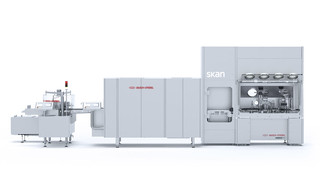

充填および密閉モジュール

マシンタイプ KSF 5105

マシンモジュールKSF 5105は、VarioSys生産システム内でボトルおよびバイアルの充填・密閉を行います。充填ステーションは、ロータリーピストンポンプを使って液体製品を充填するために設計されています。しかしながら、これにはペリスタリックポンプやタイムプレッシャー充填システムといった代替充填テクノロジーを装備することも可能です。弊社のアドオン粉末充填モジュールを使えば、粉末製品も充填できます。注入サイクルの後、容器は完全自動で密閉されます。この際使われるクロージャーには2つのタイプがあります。挿入クロージャーとシンプルなクリンプキャップ、ならびにフリップオフキャップ、フリップトップキャップ、フリップテアキャップ等の予め組み立てられたキャップ類が、確実かつ丁寧に処理されます。マシン全体の構造コンセプトに従い、このモジュールは粒子の発塵をあくまでも最小限に抑えつつ、クロージャーをピックアップ位置にフィードするために設計されています。

弊社の革新的かつ非常に汎用性が高いVarioSys生産システムに関する詳細は、ここをご覧ください:

www.variosys.com

弊社の革新的かつ非常に汎用性が高いVarioSys生産システムに関する詳細は、ここをご覧ください:

www.variosys.com

ハイライト

- モバイル、省スペースのアイソレータ内生産システム

- 液体または粉末製品

- 最大2タイプのクロージャー

- 1~100%工程内制御を行うスケール

| マシンタイプ | 出力 | プロセスレンジ |

|---|---|---|

| KSF5105 |

|

|

製薬向け設計

簡単な集中操作

コンパクト設計

低発塵ゴム栓供給

- 代替充填システム

- 100%工程内管理 (IPC)

- ゼロロスのスタートアップと製品損失を最小限に抑えた終了運転

- 充填後および密封中のガスフラッシング

- 最適化されたクロージャー供給のためのビン/フィードユニット

- 一連の検査・アラーム機器やカウンター

- ソフトウェアのアップグレード

- 適格性確認 (IQ/OQ)

ADVANCEDfill ensures that optimal use is made of your product batch.

ADVANCEDfill is a highly effective solution for processing your product. All containers in a batch are filled to the optimal level so that, at most, only the last container may need to be rejected. The ADVANCEDfill dosing system is equipped with a freely positionable needle holder. Product is dispensed directly into containers on the scales during start-up and running empty. This allows dose quantity to be monitored and setpoint deviations to be corrected in situ.

Benefits of the ADVANCEDfill dosing system:

- No need for manual intervention in the dosing area, e.g. during start-up or running empty

- Optimal product utilization

- Availability from batch sizes as small as 1

- Resource-friendly technology

G-Con PODs® Unique cleanroom infrastructures

The standard POD cleanroom unit is comprised of classified space (shown center), personnel and material airlocks (left) and a mechanical space (right). The mechanical space typically contains an air handling unit, the fire suppression system, and control/access points for utilities. Ductwork from the air handler to the clean space, integrated process piping, and fire suppression piping is contained inside the POD ceiling plenum for efficiency and compactness.Dosing systems

Rotary piston pumpsThe rotary piston pumps comprise only two parts. The dose is defined by the pump stroke setting. They are self-priming and dispense pharmaceutical products very gently and with great precision.

Single-hose peristaltic pumps

Only one product hose is required from the product vessel to the dosing needle. The single-hose peristaltic pumps do not require a Y-manifold, which means that the dosing system itself is very straightforward and easy to use.

Time/pressure dosing system

Product is supplied from a dosing vessel equipped with a precision pressure controller. Only one product hose is required from the pressure controller to the dosing needle. This electronically controlled dosing process allows production data to be acquired and documented.

smartline

Are you looking for an approved off the shelf machine concept with short delivery times, but still want to be able to optimize your line to suit your specific needs?By choosing our smartline concept you can select your personal solution from pre-engineered options and still maintain your flexibility. smartline guarantees a more efficient project workflow. Maintenance, qualification and spare parts procurement are not only faster, but also easier to handle over the entire life cycle of the line. Eliminate time-consuming engineering phases and benefit from reliable solutions that come ready to use straight out of the box.

Zero Reject

The Zero Reject Principle is a concept centered around technical features with a clearly defined goal: maximizing efficiency for our customers. The aim is to avoid product loss, be it due to overfilling or underfilling, missing closures or difficulties with the supply of product supply to the individual dosing positions. To mitigate these and other potential factors that could negatively impact efficiency and output, we offer the following solutions as part of our standard portfolio:- 100 % IPC bei voller Leistung

- Re-stoppering

- Refilling on the weighing cell

- Re-capping

- Crimp-Cap-Inspektion