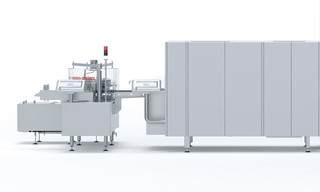

Sterilizing tunnel

Machine type DHT 2431

The sterilizing tunnel of the DHT series dries, sterilizes and depyrogenizes glass containers using a low-turbulence vertical air flow. The sterilizing-grade filters or integrated high-efficiency particulate air filters (HEPA filters) do not require any sealing on the air discharge side. Special hot gas filters in the sterilization zone produce a cleanroom class A atmosphere in all operating conditions (even during the pre-heating and cooling phases). The tunnels have multiple insulation layers to prevent heat loss and maximize energy efficiency.

HIGHLIGHTS

- Low-turbulence, vertical air flow for optimal heat transfer

- Precise maintenance of production parameters

- Gentle container heating

- High energy efficiency

| Type of machine | Processing range |

|---|---|

| DHT2431 |

|

B+S hot gas filter with long filter life

Easy and centralized operation

Pharmaceutical design

- Special Bausch+Ströbel hot air filters in the pre-heating zon

- Vane wheel anemometers for air velocity measurement in the pre-heating, sterilizing and cooling zones, with display on the operating panel or recording on a multichannel process recorder

- A range of checking and alarm devices and counters

- Software upgrades

- Qualification (IQ/OQ)